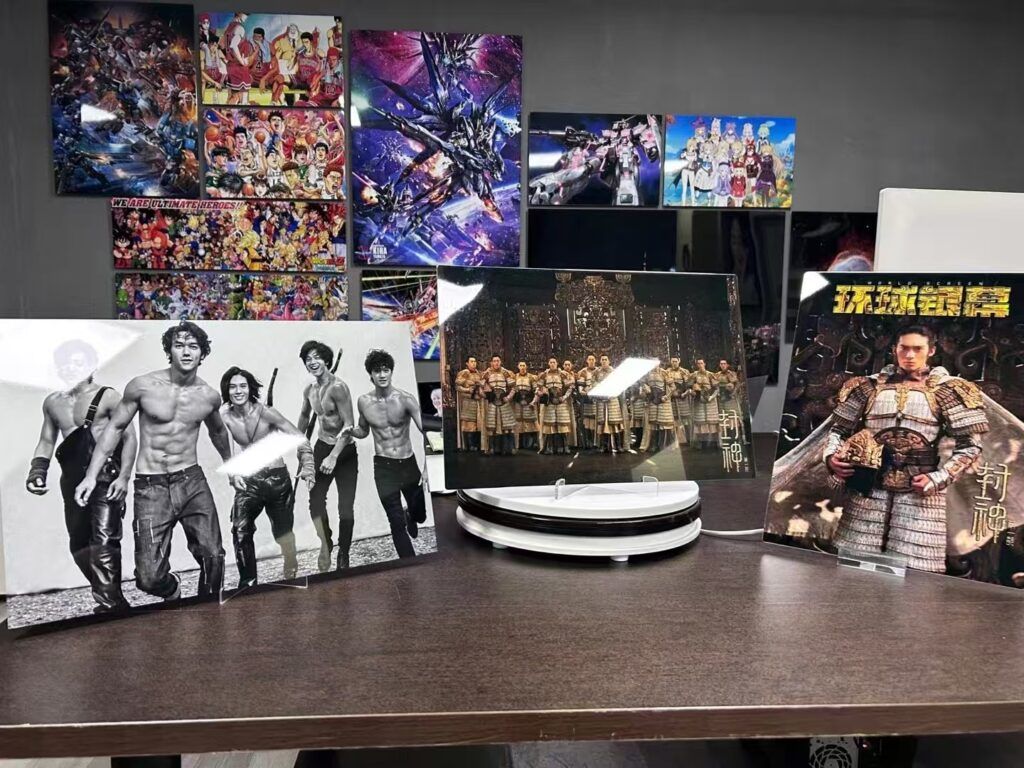

Metal print has become a popular wall art. If you are new to metal print, it is essential to understand the different uses of sublimation aluminum sheets. Our aluminum plates have more than 20 colors and a variety of thicknesses, and it’s helpful to know this for your metal print customization!

1. Understanding the Basics of Heat Sublimation on Aluminum

Heat sublimation is a process where sublimation inks are transferred onto a substrate using heat and pressure. In the case of aluminum, the process requires specialized aluminum sheets that are coated with a polyester film or coating. This coating allows the dye to bond with the aluminum’s surface, resulting in sharp, vibrant images with high durability.

The key advantage of sublimation aluminum sheets is its ability to produce prints with exceptional color reproduction and long-lasting durability. Aluminum panels can withstand the elements, making them ideal for both indoor and outdoor applications.

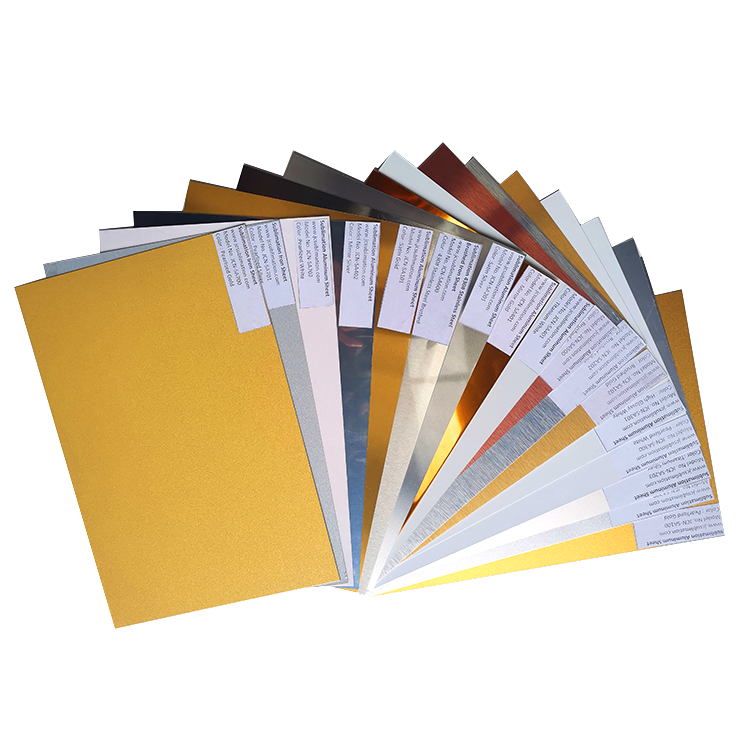

2. Types of Aluminum Sheets for Sublimation

a. Glossy White Sublimation Aluminum Sheets

Glossy white aluminum sheets are the most common and versatile option for sublimation. These panels are coated with a white polyester coating that provides a smooth, even surface for sublimation. The white coating ensures that colors appear bright and true to life, which is why these sheets are used in a wide variety of applications, including photo panels, signage, and custom gifts.

b.Matte White Finish Sublimation Aluminum Sheets

Aluminum panels are available in both glossy and matte finishes. The finish you choose depends on the desired look of the final product.

Glossy finishes give the print a shiny, vibrant look, while matte finishes offer a more subdued, refined appearance.

c. Brushed Gold and Sliver Aluminum Sheets

Brushed sublimation aluminum sheets have a textured surface that gives the finished print a sleek, metallic appearance. The brushed surface creates a unique effect that can add dimension and texture to a print.

3. Thickness of Sublimation Aluminum Sheets

For sublimation, the thickness of the aluminum sheets is another equally important factor.Thicker sheets are more durable and resistant to bending. Thinner sheets are lighter and easier to handle. Thicker panels come at a higher cost.

0.35mm/0.45mm:suitable for medals.

0.65mm: Ideal for ornaments, license plates and other small crafts.

1.15mm: the thickest thickness, strong and durable, not easy to bend, suitable for metal print and other display purposes.

4. Intended Use and Durability

The intended use of your sublimated aluminum print will guide your choice of panel. If you’re creating products for high-traffic areas or outdoor displays, choosing an aluminum panel with UV protection and a tough, scratch-resistant coating is essential.

The coating and professional ink on the sublimation aluminum sheets determines that the color will not fade easily, and can be maintained for decades indoors, but only last about 10 years outdoors.

Choosing the right aluminum sheets for heat sublimation is vital to producing stunning, durable prints. Consider factors like the type of finish, thickness, coating quality, and the intended use of the final product. By understanding these elements and making an informed choice, you’ll ensure that your prints look professional and last for years to come.

Ultimately, selecting the right sublimation aluminum sheets comes down to balancing quality, cost, and application needs. Whether you’re printing for a gallery show, creating personalized gifts, or producing signage for outdoor use, investing in the right materials will ensure your sublimation metal prints achieve their full potential.