Sublimation metal blanks are a popular choice for creating personalized products, from custom photo panels to branded business items. These blanks are pre-coated with a special coating that allows images to be transferred onto the surface using heat and pressure. This process creates vibrant, long-lasting prints that are resistant to fading and wear. In this post, we’ll explore what sublimation metal blanks are, their advantages, and how they can be used in various applications.

What are Sublimation Metal Blanks?

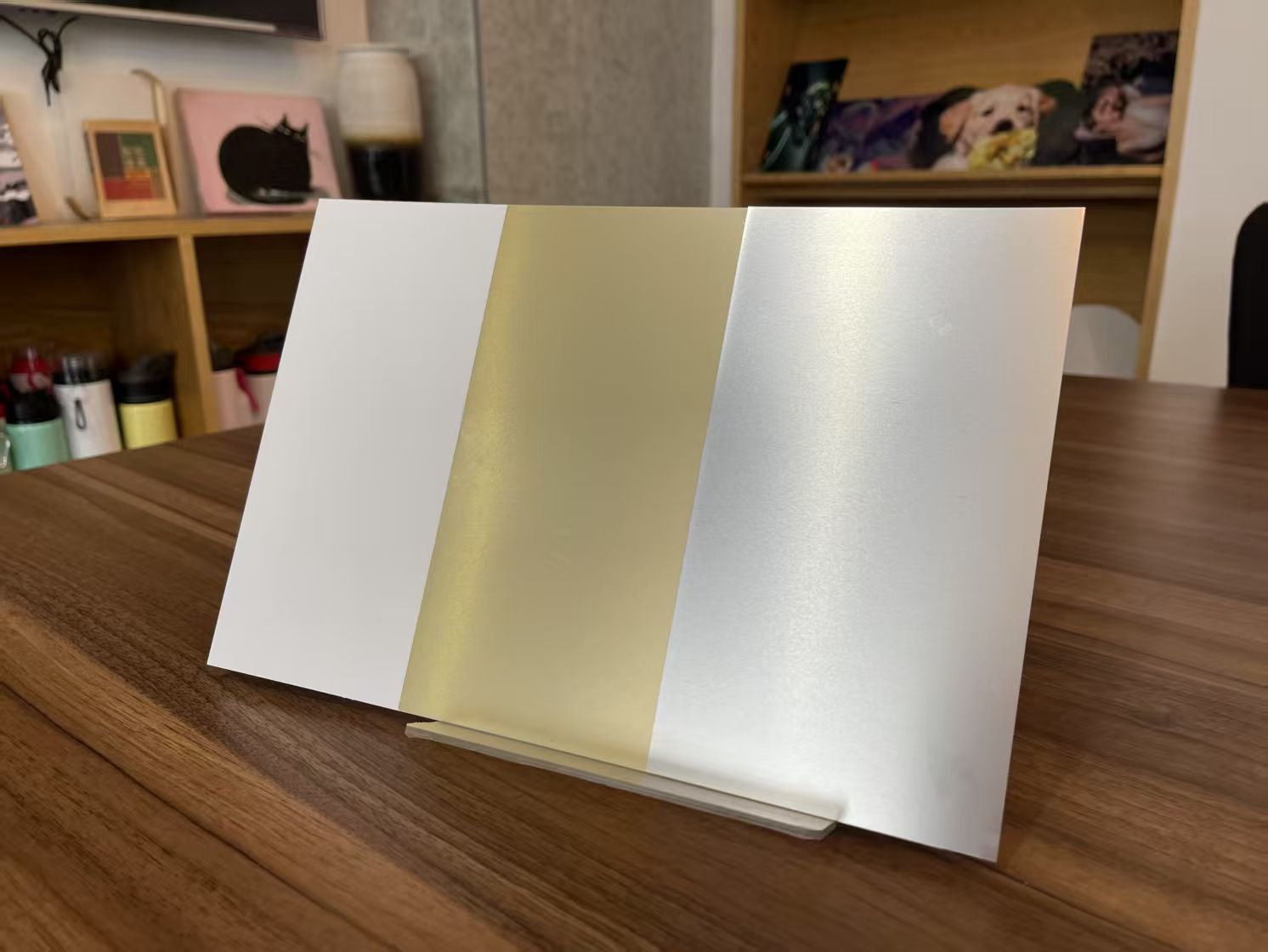

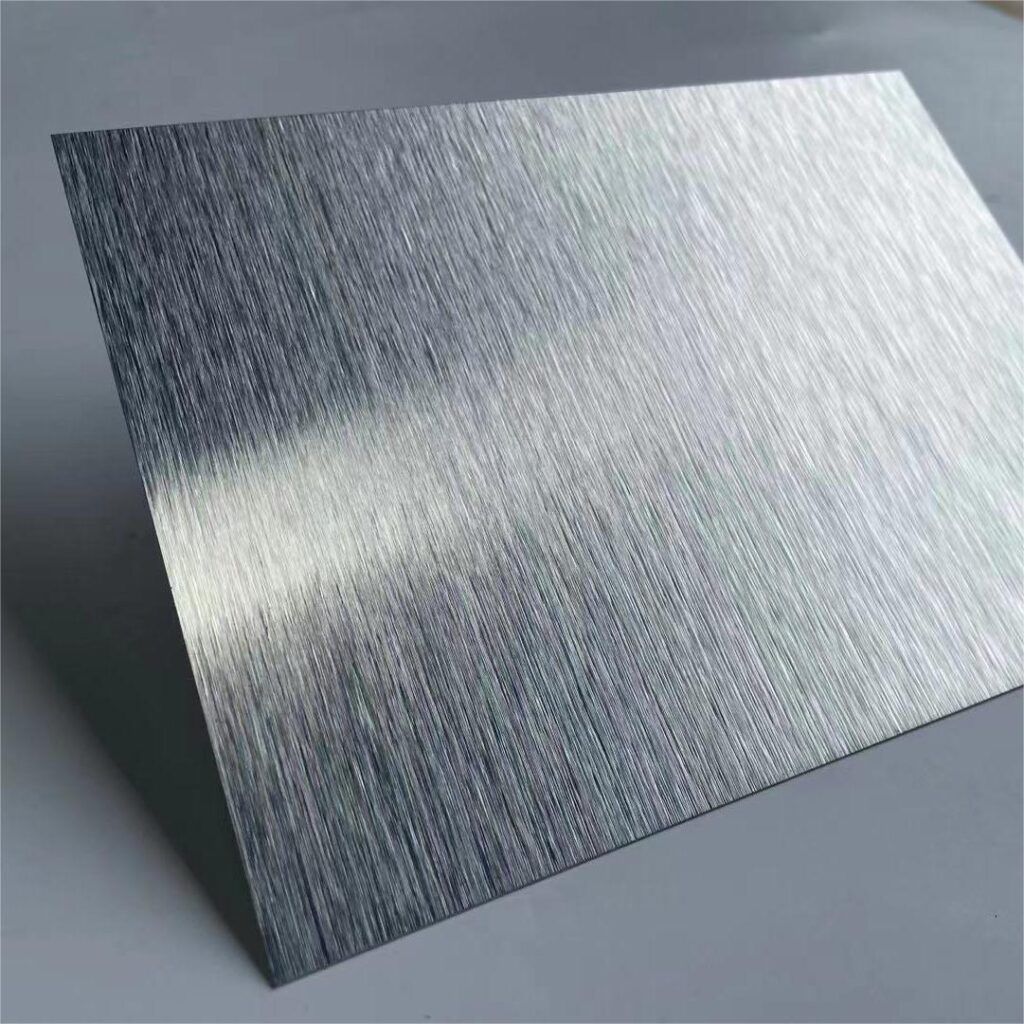

Sublimation metal blanks are flat sheets of metal, usually aluminum, that have been coated with a polymer layer designed for heat transfer. This coating is what makes the sublimation process possible. When the blank is heated, the ink from a sublimation printer turns into gas and bonds with the surface, creating a permanent and durable print.

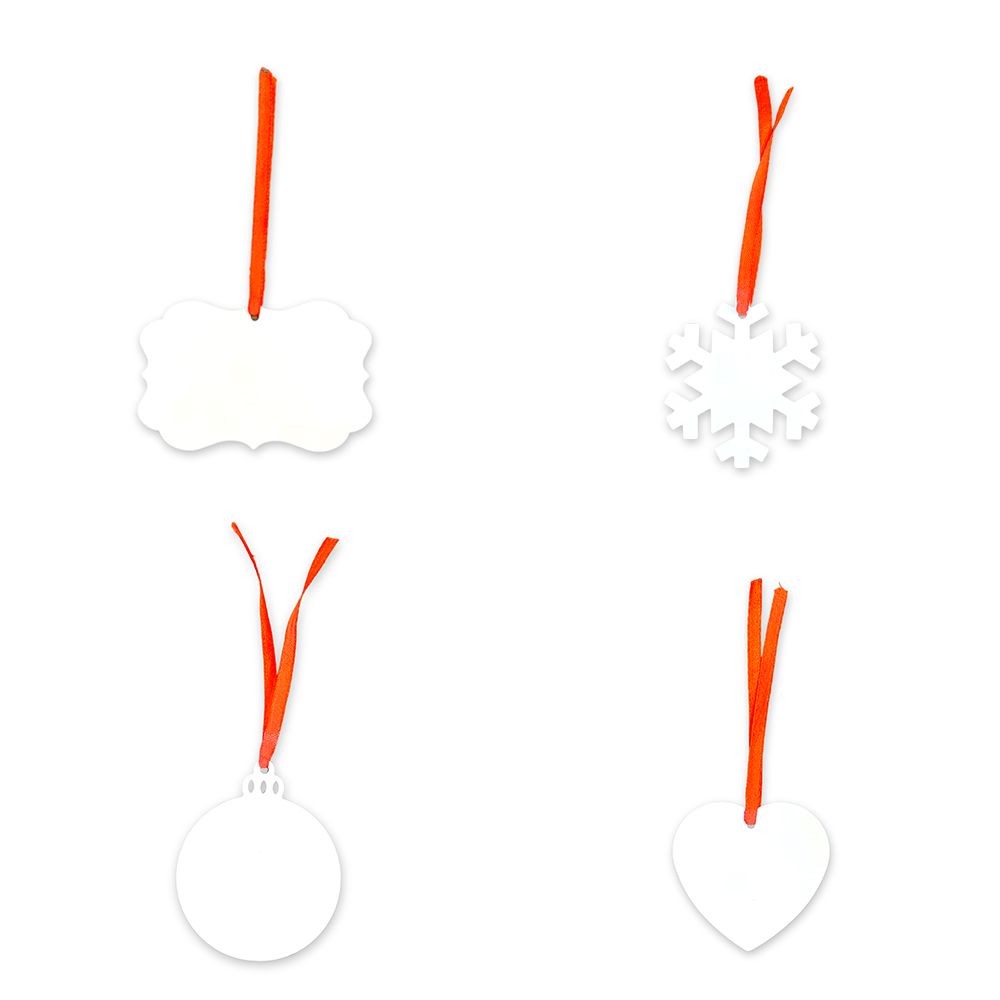

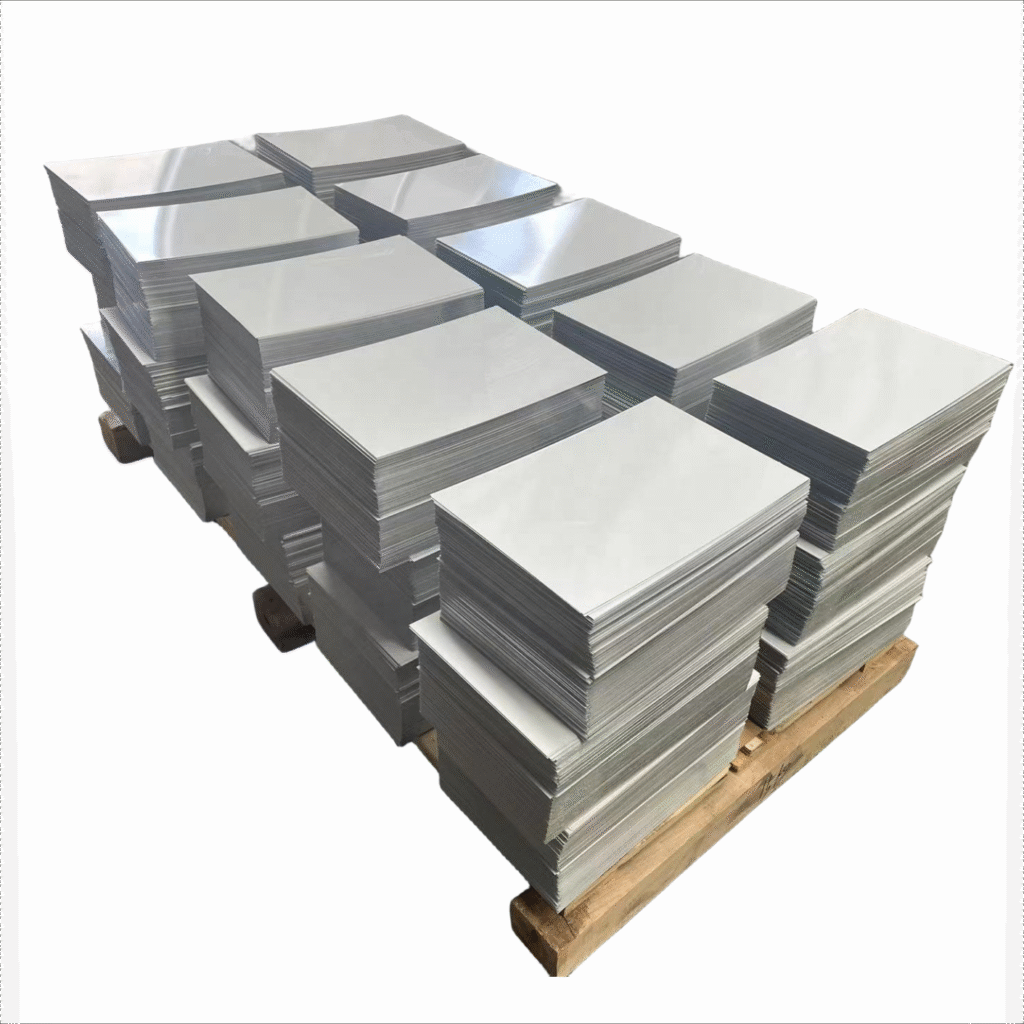

These blanks come in various sizes, shapes, and finishes, including matte, gloss, and satin. They can be used for a wide range of projects, from photo gifts and awards to signage and promotional materials.

Benefits of Using Sublimation Metal Blanks

1. Durability

One of the biggest advantages of sublimation metal blanks is their durability. Once the design is transferred, the print becomes part of the surface of the metal, meaning it won’t peel or fade like traditional prints. This makes sublimation metal blanks ideal for both indoor and outdoor products.

2. Vibrant, Full-Color Prints

Sublimation is a process that can produce bright, high-definition prints with a full spectrum of colors. The smooth surface of the metal allows for sharp, crisp details and vibrant color reproduction, making it perfect for photos, logos, and artwork.

3. Versatility

These blanks can be used for various applications, from creating custom gifts such as photo plaques and ornaments to making business signage, name tags, and even license plates. They can also be used for large-format designs, as many sublimation metal blanks come in large sizes.

4. Weather and Scratch Resistance

Due to the nature of the sublimation process, prints on metal blanks are highly resistant to scratches, UV light, and weather conditions. This makes them perfect for products that will be exposed to outdoor elements, such as signs, plaques, and other promotional items.

Applications of Sublimation Metal Blanks

Sublimation metal blanks can be used in a variety of industries and applications, making them highly versatile and widely sought after.

Personalized Gifts

Custom photo gifts are a popular use for sublimation metal blanks. Items like photo panels, ornaments, and keychains can be easily personalized with family photos, artwork, or meaningful designs. These items are often used for special occasions such as birthdays, weddings, and anniversaries.

Corporate Branding and Promotional Items

Businesses use sublimation metal blanks to create branded items like keychains, pens, and nameplates. These products are often given as corporate gifts, or used for employee recognition or customer giveaways. Custom metal name tags and desk plaques are also common promotional items.

Awards and Recognition

Sublimation metal blanks are an excellent choice for creating custom awards, trophies, and recognition plaques. Their durability and professional appearance make them ideal for commemorating achievements or milestones.

Signage and Decorative Pieces

Metal blanks can be used for signs, wall art, and other decorative items. These can be customized with logos, quotes, or images, making them a popular choice for home décor and business signage. Their sleek and modern look is perfect for both personal and commercial spaces.

How to Use Sublimation Metal Blanks

To achieve the best results with sublimation metal blanks, it’s essential to follow a few key steps:

1. Prepare Your Design

Start by designing your image or artwork in a graphic software program like Adobe Illustrator or Photoshop. Make sure the design is high resolution and correctly sized for the blank you’re using.

2. Print the Design

Print your design using sublimation ink and transfer paper. The image should be printed in reverse (mirror image) so that it appears correctly on the metal blank.

3. Heat Pressing

Place the metal blank on the heat press, making sure it is positioned correctly. Apply the printed transfer paper on top of the blank, and press with the correct temperature, time, and pressure settings. The heat will cause the ink to sublimate and bond with the metal.

4. Cooling

After the press is complete, allow the metal blank to cool before removing the transfer paper. Once cooled, the design should be permanently bonded to the surface.

Sublimation metal blanks offer a powerful solution for creating customized, durable, and vibrant products. Their versatility, long-lasting results, and wide range of applications make them a popular choice for both personal and business projects. Whether you’re looking to create personalized gifts, promotional items, or decorative pieces, sublimation metal blanks provide an excellent medium for bringing your designs to life.