Sublimation printing has become one of the most popular methods for creating vibrant, long-lasting graphics. At the heart of this process lies the dye-sublimation graphic substrate—a specially coated surface designed to achieve high-quality prints. Whether you’re a business owner, print shop operator, or DIY enthusiast, understanding graphic substrates will help you select the right materials and achieve outstanding printing results.

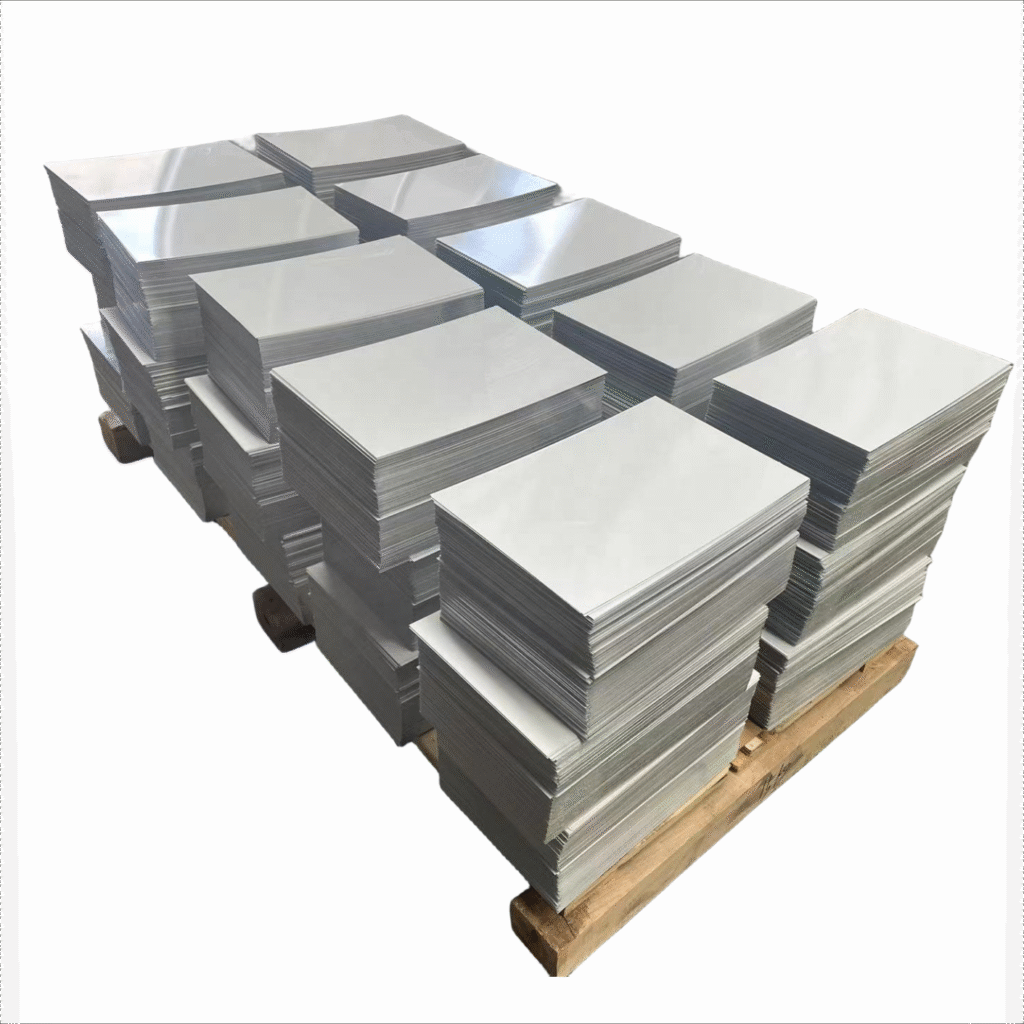

What Are Sublimation Sign Blanks?

The blank for sublimation printing are pre-cut surfaces coated with a polymer layer that accepts sublimation ink through heat press application. Unlike standard materials, these blanks feature a polymer coating that permanently bonds the dye to the surface. This ensures the printed design will not peel, fade, or crack over time.

Common materials for sublimation sign blanks include:

Aluminum: Durable, weather-resistant, and ideal for both indoor and outdoor signage.

MDF or Hardboard: Affordable and lightweight, perfect for indoor use.

Plastic or Acrylic: Flexible and often used for customized signs with unique shapes.

Advantages of Sublimation Sign Aluminum Blanks

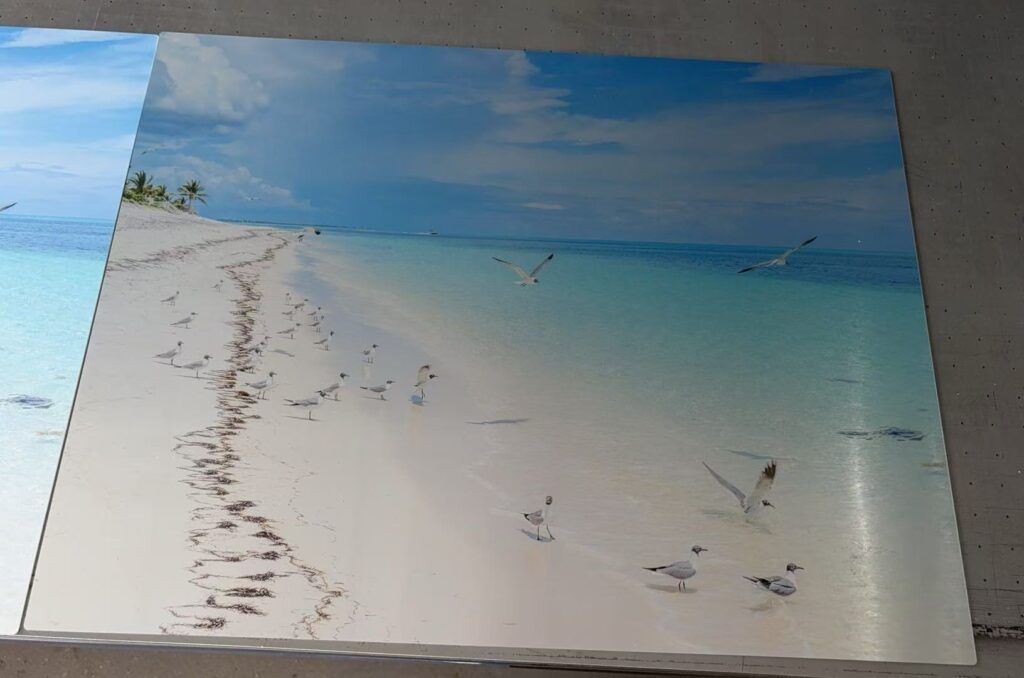

Vivid Color

The sublimation process produces sharp details and vibrant colors, ensuring signs stand out.

Durability

Prints are infused into the surface, making them resistant to scratching, fading, and moisture.

Versatility

Sublimation aluminum blanks come in a variety of sizes, shapes, and finishes—glossy, matte, brushed metal, and even textured options.

Customization

They allow full personalization, making them ideal for business branding, events, or decorative signage.

Common Applications

Sublimation sign aluminum blanks are widely used in both commercial and personal projects. Some popular uses include:

Business Signage: Storefront signs, nameplates, and directional signs.

Decorative Signs: Home décor, inspirational quotes, or wall art.

Event Displays: Customized signs for weddings, parties, and trade shows.

Promotional Products: Branded giveaways or personalized gifts.

How to Print on Sublimation Sign Blanks

Design Preparation

Create your design using graphic software, ensuring the correct size and bleed area for your blank.

Printing

Print the design on sublimation paper using sublimation ink.

Heat Press Transfer

Place the transfer paper on the blank area, then use a heat press with the recommended temperature, pressure, and time settings.

Cooling and Finishing

Allow the blank to cool before removing the paper, revealing a permanent, vibrant design.

Choosing the Right Sublimation Sign Blanks

When selecting blanks, consider:

Application Location: Outdoor projects can utilize UV-printed aluminum, which retains its color for decades. For indoor applications, sublimation aluminum sheets are recommended for easy cleaning.

Finish Preference: Glossy surfaces enhance vibrant designs, while matte finishes reduce glare.

Size and Shape: Choose blanks that match your intended design and purpose.

Sublimation sign blanks offer professional, durable, and customizable signage solutions. From small personalized plaques to large outdoor displays, the possibilities are virtually endless. By selecting the right materials and applying appropriate printing techniques, you can create signage that combines aesthetic appeal with long-lasting performance.

Looking for high-quality sublimation aluminum blanks? Our company specializes in producing premium sublimation aluminum sheets and sign blanks. We stock dozens of colors, finishes, and sizes, offering fast shipping and reliable quality to meet your business or creative needs. Contact us today to explore our full range of sublimation aluminum blanks and bring your signage projects to life.