Metal printing on sublimation aluminum sheets is a popular method for creating vibrant, long-lasting printed designs, commonly used for personalized gifts, home decor, and commercial signage. However, many people have questions about this process, its advantages, and how to achieve the best results. Below are some frequently asked questions about sublimation printing on aluminum sheets.

1. What is Sublimation on Aluminum Panels?

Thermal sublimation is a printing technique that transfers dye onto surfaces using heat. When applied to aluminum plates, the dye directly penetrates the metal surface, producing vibrant, long-lasting prints that resist fading, scratching, and peeling.

How it Works: The dye is heated to a gaseous state and bonds with the aluminum surface. The aluminum plate must be pre-coated with a special polymer coating to ensure effective dye bonding.

2. What Are the Advantages of Sublimation on Aluminum Panels?

Compared to traditional printing methods, sublimation offers numerous advantages.

Durability: Prints using aluminum sublimation technology resist fading and are exceptionally durable, even when exposed to harsh environmental conditions.

Vibrant colors: This process enables high-resolution, full-color printing, producing vivid and rich colors.

Scratch-resistant: Unlike traditional prints that may peel or scratch, sublimation creates permanent images that won’t fade or wear over time.

Weather resistance: Sublimation aluminum panels are highly suitable for outdoor use, withstanding UV radiation, moisture, and extreme temperatures.

3. What Types of Aluminum Sheets Are Used for Sublimation?

Not all aluminum sheets are suitable for sublimation transfer printing. The aluminum sheet used must be coated with a special polymer coating to ensure the dye bonds properly.

Coated aluminum panels: These panels are pre-coated with polyester or polymer coatings, enabling dyes to bond effectively during the sublimation process.

Uncoated aluminum: Uncoated aluminum cannot be used for sublimation printing because the dye will not adhere to the surface.

4. What Can I Print on Sublimated Aluminum Panels?

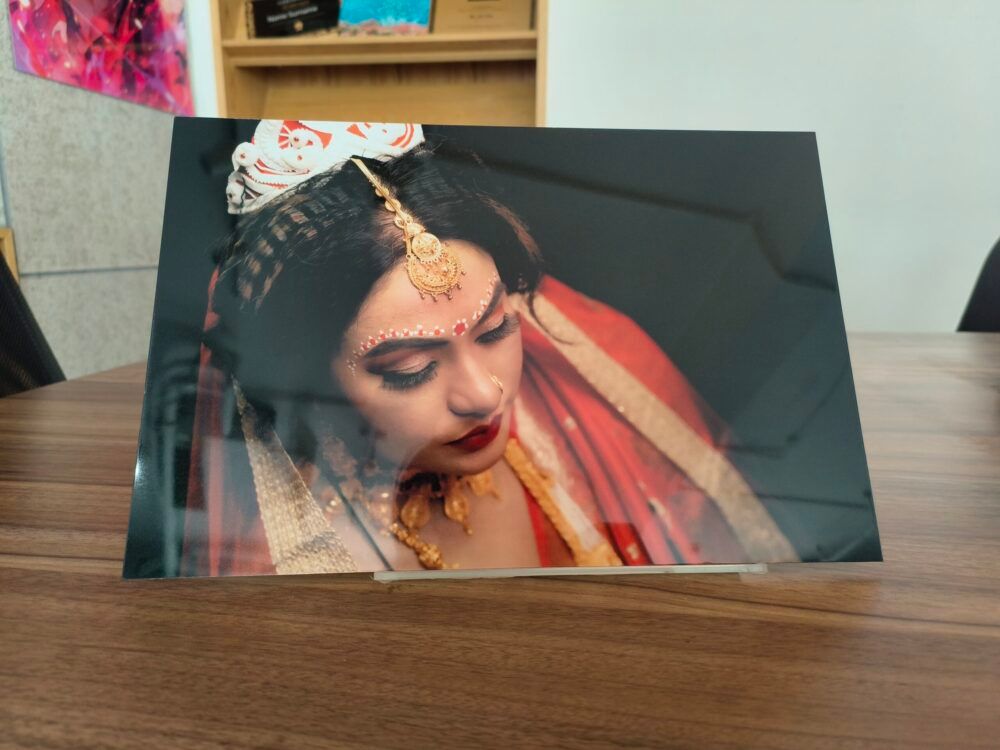

Home Decor: Custom aluminum prints can be used for wall art, signage, and decorative items.

Personalized Gifts: From photo prints to custom messages, elevated aluminum panels are a popular choice for personalized gifts.

Commercial signage: Sublimation is commonly used to produce durable signage, including company logos, street signs, and more.

5. What Is the Process for Sublimating Aluminum Sheets?

The sublimation process involves several key steps:

Preheat the heat press machine: Heat is the key factor in sublimation, so the first step is to preheat the heat press to the required temperature.

Prepare Your Design: Print your design onto special sublimation paper using sublimation ink. To ensure colors do not appear too dark, set your document to RGB color mode and configure the ICC print profile beforehand.

Transfer Design: Using a heat press machine, apply the printed sublimation paper onto the pre-coated aluminum plate, ensuring uniform pressure and temperature across the entire surface.

Cooling: After transmission is complete, allow the panel to cool before proceeding with processing.

6. What Are the Ideal Temperature and Time Settings for Sublimation?

The optimal temperature and time for sublimation aluminum sheet may vary slightly depending on the equipment used, but the general guidelines are as follows:

Temperature: 375°F to 400°F

Time: 60 to 120 seconds

It is crucial to set the specific temperature and time settings for the testing equipment and panels to ensure optimal results.

7. Can I Sublimate on Both Sides of the Aluminum Panel?

Although both sides of aluminum sheets can undergo sublimation, it’s important to note that typically only one side is coated with the necessary polymer layer. Therefore, only the coated surface can effectively carry sublimation ink. If needed, you can purchase specialized sublimation aluminum sheets with a coating on the back side.

8. How Do I Maintain Sublimated Aluminum Prints?

To keep your sublimated aluminum prints looking their best:

Avoid using harsh chemicals: Clean printed items with a soft cloth and mild soap or detergent. Avoid using harsh chemicals or abrasive cleaners.

Proper Storage: When storing printed materials, keep them in a cool, dry place away from direct sunlight to prevent fading over time.

9. Can I Use Sublimation for Outdoor Signs?

Yes, sublimation printing is an excellent choice for outdoor signage. The durability of sublimation-printed aluminum, combined with its UV resistance, moisture resistance, and tolerance to temperature fluctuations, makes it an ideal solution for outdoor environments.

10. What Are the Costs Involved in Sublimation?

The costs involved in sublimation printing can vary depending on several factors, including:

Cost of Equipment: A heat press machine is required, along with a printer that uses sublimation ink.

Cost of Materials: The aluminum panels, sublimation paper, and ink all contribute to the overall cost.

Time and Labor: The time it takes to prepare and process each print also plays a role in pricing.

Sublimation printing on aluminum sheets is a powerful printing method offering durability, vibrant colors, and long-lasting results. Whether you’re creating custom gifts, home décor, or outdoor signage, this technology proves versatile and reliable. By understanding the key steps of the process and following best practices, you can achieve high-quality sublimation results every time.