Choosing the right sublimation aluminum sheet supplier is crucial to ensure the quality, consistency, and success of your printing projects. This post will walk you through what sublimation aluminum sheet is, its common uses, and how to select the right supplier for your needs.

What Is Sublimation Aluminum Sheet?

Sublimation aluminum sheet, also known as dye-sublimation aluminum or sublimation metal, is a specially coated aluminum sheet designed for high-quality image transfer through heat and pressure. During the heat press process, solid dye ink turns into gas and penetrates the polymer coating on the aluminum surface. The result is a vibrant, high-resolution image that is infused into the metal, offering exceptional durability and visual appeal.

Unlike traditional printing surfaces, the image becomes part of the material, not just printed on top of it.

Common Uses of Sublimation Aluminum Sheet

Photo Panels: For personal or commercial wall art, offering brilliant color reproduction and longevity.

Awards and Plaques: Made from brushed gold silver sublimated aluminum sheets, durable and professional-looking, ideal for corporate or academic recognition.

Signage: Indoor or protected outdoor signs that require vivid visuals and moisture resistance.Outdoor signage can use UV printing, can be used for decades without fading.

Nameplates: Used in manufacturing, retail, and branding, offering clear identification and long-term wear.

Decorative Ornaments: For furniture, interior design, or customized home products.

Key Factors to Consider When Choosing a Supplier

The quality of sublimation aluminum sheet directly influences your finished product. That’s why making the right choice from the beginning is essential.

When evaluating a sublimation aluminum sheet supplier, consider the following points:

1. Product Range

Ensure the supplier offers a variety of aluminum sheet finishes (glossy, matte, satin, brushed, etc.), sizes, and thicknesses to meet your project needs.

2. Customization Options

Some suppliers provide pre-cut panels, corner rounding, or protective films. These options can save you time and improve workflow efficiency.

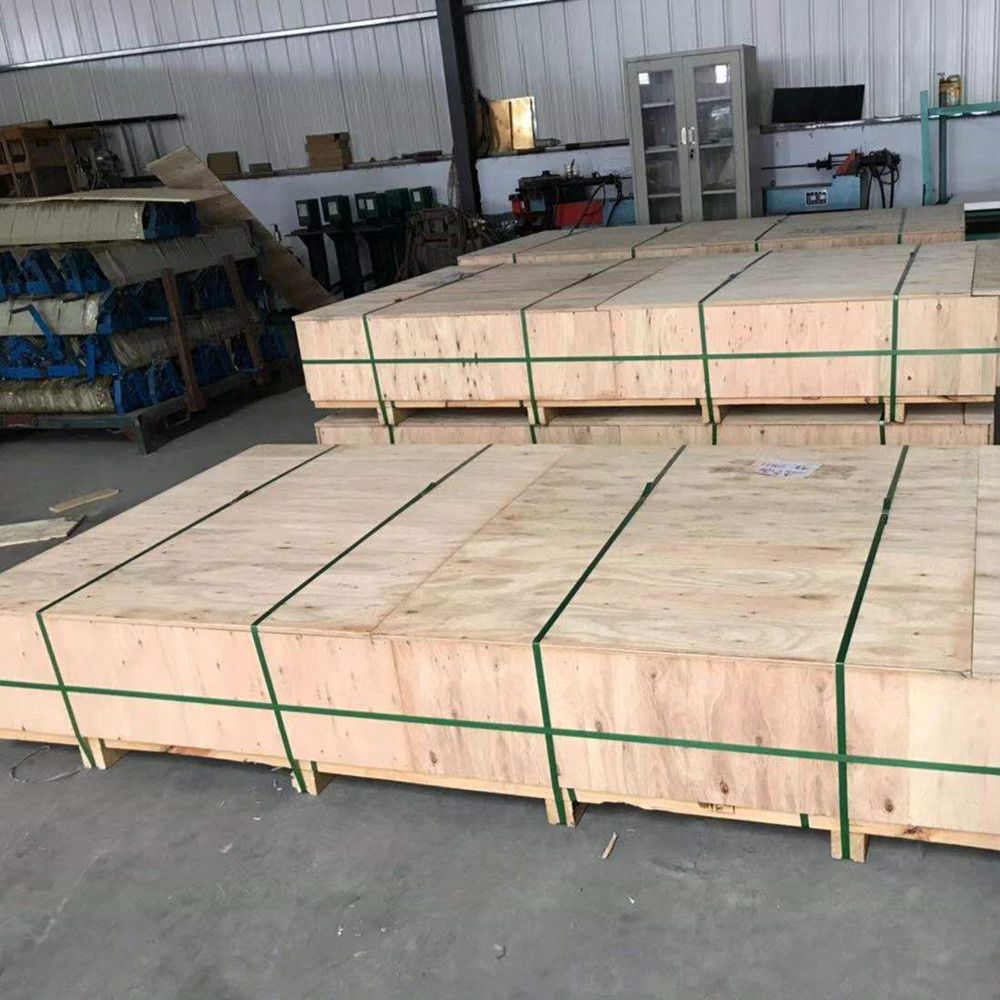

3. Lead Times and Logistics

Ensure that your suppliers have adequate aluminum stock inventory and convenient logistics, which can save you a lot of time.

4. Customer Service

Choose a supplier that offers responsive communication, technical support, and after-sales service. A good partner is more than just a material provider—they support your success.

Our company has more than 20 colors of aluminum sublimation sheets to choose from, including several thicknesses from 0.22mm to 1.15mm, to fully meet your various product needs.We have over a dozen tons of sublimated aluminum sheets in stock that can be shipped in as little as 7 days.

We have professional CNC cutting machine, support customized various shapes and sizes, cutting round corners. In addition to sublimation aluminum sheets and crafts, we also have matching metal brackets, on-wall magnets to fully display the metal print.

If you are new to metal print, we can provide you with one-stop shopping and service. If you need, we will recommend the heat transfer machine, corner rounding machine and cutting machine. We also sell professional heat transfer paper and heat transfer ink.

Sublimation aluminum sheet is a premium medium that deserves premium materials. Whether you’re creating vibrant wall art or durable industrial labels, the right supplier ensures your work looks professional, lasts longer, and meets your clients’ expectations. Take the time to evaluate your options carefully—it’s an investment that will pay off in both quality and peace of mind.