Compared to traditional photographs, metal prints are more durable, scratch-resistant, easy to clean, and resistant to fading. No additional frames are required, as metal prints can be displayed freely. Metal prints feature more vibrant and vivid colors than those printed on flat surfaces. The principle behind metal prints involves thermal transfer, where pigment molecules sublimate at high temperatures and fuse with the metal surface. If you are new to metal prints, it is essential to understand the thermal transfer process. This blog post will guide you through the entire process from image to final printing, explaining the rationale behind each step and potential issues to avoid material waste.

Common material for metal prints

Sublimation aluminum sheet:

Sublimation aluminum sheets have different kinds of color and thickness, including high-gloss white, brushed gold, brushed silver, pearlized gold, and pearlized silver, among others. The thickness ranges from 0.22mm to 1.15mm. Sublimation aluminum sheets are made of aluminum with a polyester coating on the surface. Through the thermal sublimation process, pigments are integrated into the coating, achieving a perfect fusion of patterns and metal.

If you are creating metal prints, the most common choice is the 1.15 mm glossy white sublimation aluminum sheet. The glossy white sublimation aluminum plate has a lustrous finish, making it ideal for displaying various patterns. The 1.15 mm thickness is resistant to bending.

Sublimation printer: A professional sublimation printer with sublimation inks

Sublimation paper: Print your desired picture with sublimation paper

Heat-resistant tape: Secure the sublimation aluminum sheet with heat-resistant tape.

Heat-resistant gloves: The heat transfer machine reaches temperatures as high as 200 degrees, so you need a pair of heat-resistant gloves.

Heat transfer machine

Heat-resistant cloth: The heat-resistant cloth is made of breathable Teflon material, which prevents the sublimation aluminum sheet from moving.

How to sublimate sublimation aluminum panel

1.Print your picture

Choose a picture to the size of the metal print you want. The width and height of the image should be 0.2 inches larger than the selected sublimation aluminum panel. During the sublimation process, the picture will shrink, so to prevent white borders, the size of the printed picture must be larger than the sublimation aluminum panel.The picture resolution must be at least 300.

2.Remove the protective film from the sublimation aluminum sheet

Sublimation aluminum sheet has a transparent protective film to prevent contamination of the coating. After peeling off the film, avoid direct contact between your hands and the coating of the sublimation aluminum sheet, as this may affect the printing quality of the pattern.

3.Turn on the heat transfer machine

For an A4-sized sublimation aluminum sheet, the temperature is 180 degrees, and the time is 90 seconds. The temperature, time, and pressure settings depend on the size of the sublimation aluminum sheet. The larger the aluminum plate, the stronger the pressure, the higher the temperature, and the longer the time required.

4.Dye the sublimation paper

Put the printed picture on the heat transfer machine for a few seconds. Drying the moisture in the sublimation ink promotes better printing results and prevents blurring in the metal print.

5.Secure the sublimation aluminum sheet with heat-resistant tape to prevent blurring of the picture.

6.Place the aluminum panel in the heat transfer machine

The sublimation aluminum sheet on top, the sublimation paper underneath. Cover with heat-insulating cloth, and then start the heat transfer machine.

7.Remove the sublimation aluminum sheet

During the heat transfer process, temperatures can reach up to 200 degrees Celsius, so it is necessary to wear heat-resistant gloves when removing the sublimated aluminum sheet. The process of peeling off the paper should be done quickly to avoid causing the pattern to become blurred.

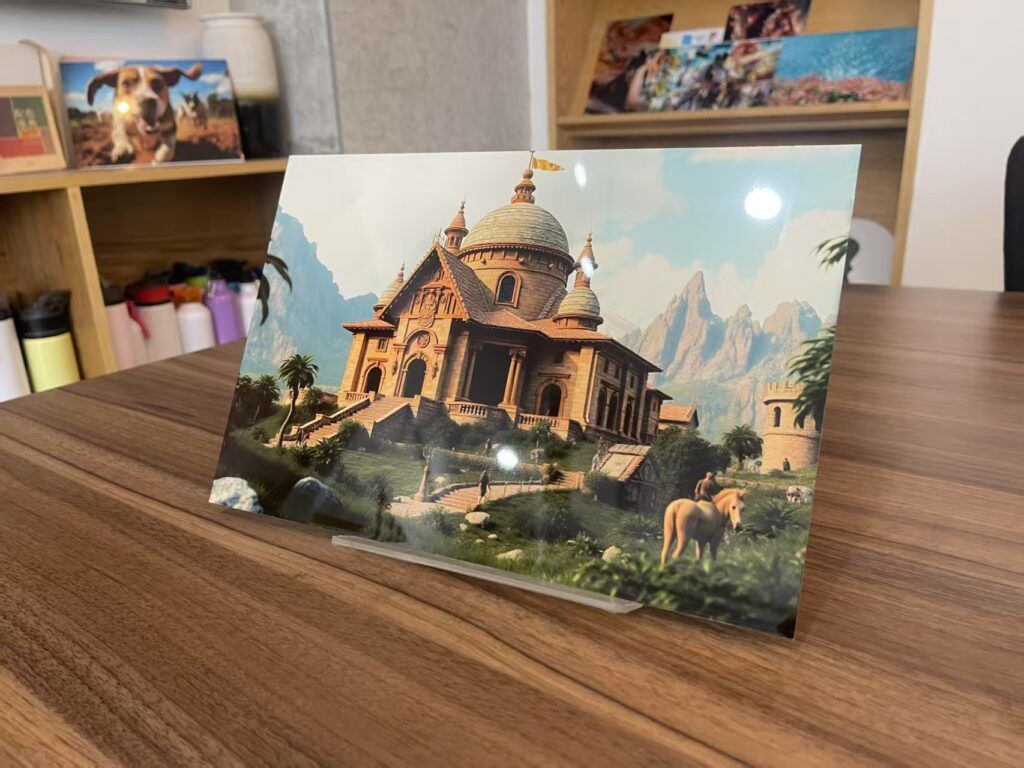

Finally get your own metal print.

Not only for photo panel, sublimation aluminum sheet also can be used for license plate, bookmark, ornament and so on. If you want to start your metal print business, please send your inquiry to us.